Design, installation and commissioning of multiple workshop and classroom equipment solutions

This project consisted of a multi-room CDT department consisting of two technicians’ prep-store areas, two large workshops where AES provided the machinery, storage equipment and C-VAC Wood Dust Extraction System. As well as the technology department, AES also assisted with the design and installation of low voltage power trunking modules within the computer lab areas and the installation of a Kiln and relating extraction system within the art department.

Scope of Works

- Full design of CDT department and specialist extraction systems

- Complete Fit-out, installation and mechanical and electrical commissioning of machinery and material storage solutions

- Installation and LEV commissioning of AES C-VAC Wood Dust Extraction System

- Provision and installation of Low Voltage modules for Computing Labs

- Installation and commissioning of Kiln unit and relating extraction solution within the Art department

Full design of CDT department and specialist extraction systems

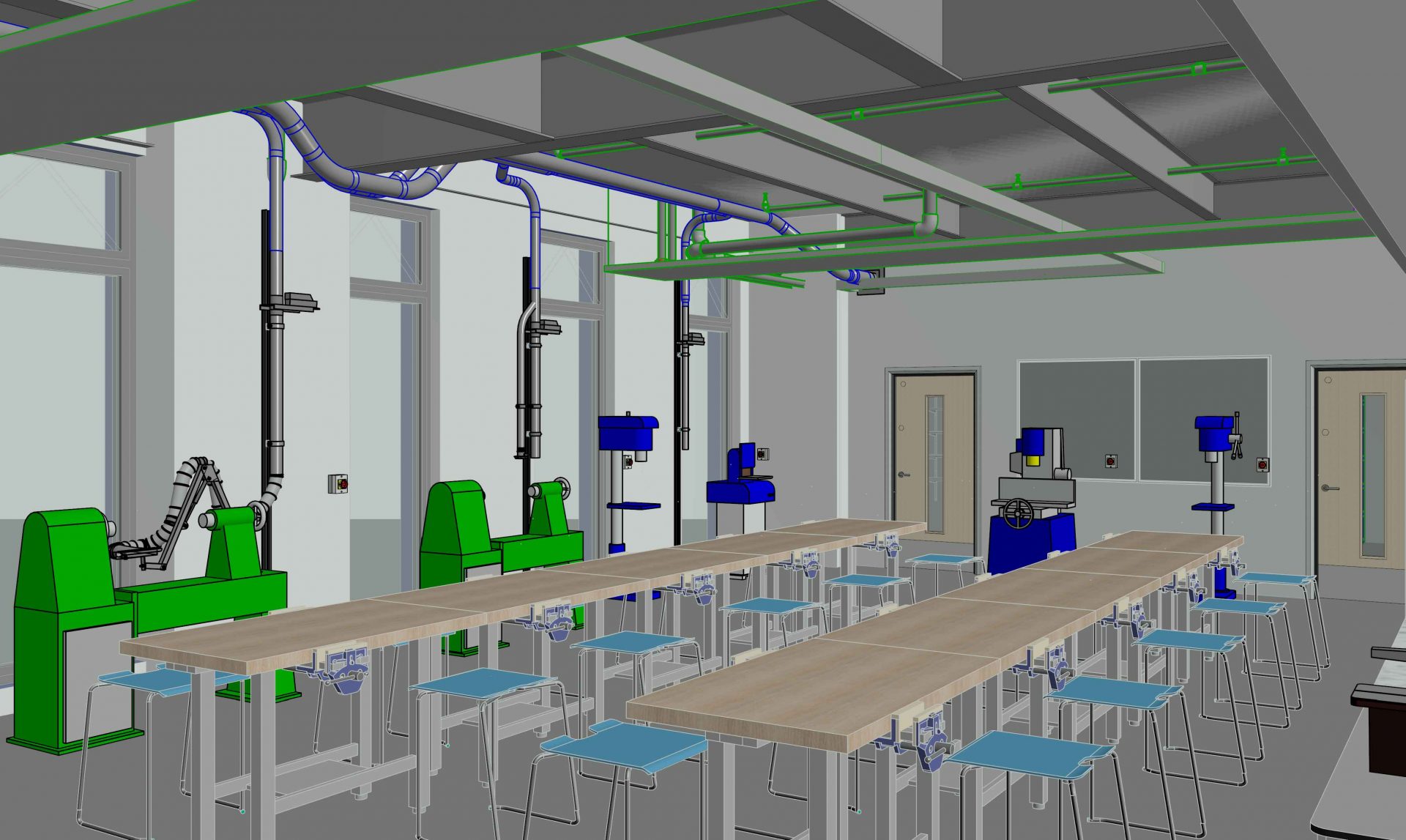

For this project AES utilized our capability with 3D CAD using Autodesk Revit to provide full layouts of the department.

As with all BIM projects We worked in conjunction with the main contractor and architect to collaborate with all internal and external services to route our extraction network throughout the various workshops, without any disruption to any existing and essential infrastructure.

AES have the ability to fully visualise any project in 3D before any works begin, allowing the client and our colleagues on site to communicate and solve any potential issues before they arise. You can see an example render in this section of the technicians prep room for this project.

CDT Department Workshops

Within the technicians preparation and store, AES installed our industry leading C-VAC extraction system connecting directly to the staff-only machinery within this area. Our design of the machinery spacing and small form factor of the C-AVAC allowed room to provide additional storage in this room for the teaching staff and technicians.

All of the fixed classroom machinery is connected to the C-VAC system via discreet small diameter ducting and throughout the workshops we have various plug in points and cleaning hoses with brushed suction nozzles for staff and students to use for floors and benches.

For the bench mounted equipment we created bespoke connections allowing machinery such as fretsaws to be connected to underbench local extraction systems.

We have also provided a full supply of hot works, metalworking and plastic moulding equipment within this facility, providing the workshops with everything they need to complete any stage of the curriculum within the department. The additional storage room between the two workshops offers a large space for the staff to use specific machinery and store metal.

Installation and LEV Commissioning of AES C-VAC wood dust extraction system.

Housed in the technicians prep room our C-VAC system is easily accessible and maintained without obstruction to any machinery, doorways or exits. The system is neatly installed in a corner of the workshop, working quietly and efficiently for the entire department.

For connection of cleaning equipment we have provided multiple plug in points throughput the workshop and various bench and floor cleaning attachments placed within each room. The plug in points are powered via tactile microswitch controlled flap valves that provide suction as soon as they are opened.

Working with a frequency inverter drive system within the panel the C-VAC is one of the most energy efficient systems on the market for education. Our design sized the system to allow the maximum amount of machinery in use at any one time during normal operation and scales the required performance depending on what equipment is in use.

When no machines are being used and no cleaning points are open, the machine automatically starts its cleaning cycle and then return to stand-by mode ready to kick in again the next time a machine is powered on.

Provision of Low Voltage Modules for Computer Labs

Upstairs from the CDT department AES also provided the full installation of low voltage modules for the computer labs within the School. These units were designed to a bespoke length to allow the maximum amount of modules for the benches within the classroom, providing the students with mains power, low voltage controls and compressed air.

AES specialize in the design and installation of these low voltage and power trunking modules, with the ability to provide a full bench mounted system that can consist of multiple connections and outlets for power, networks, fume extraction and pneumatics.

Installation of Kiln and Kiln extraction system

Within the Art department we also provided the installation and connection of a heatworker kiln unit. This piece of equipment has been designed for efficient use in Schools where multiple projects are ongoing with safety measures and effective insulation provided as standard.

In addition to the kiln installation AES provided the fitting of an extraction canopy hood connected to its own custom extraction network to vent externally from the building at a safe location, removing heat and any harmful fumes from projects from the Kiln room.

This is one of many projects where AES have provided multiple solutions throughout the facility, find out today how we could help you with your next educational project by contacting us on 0800 032 0895 or email in at info@aessolutions.co.uk

Get in touch with us today and we will help you create a safer workplace within your educational facility.

Speak to one of our technical team about your project or send us a general enquiry about or products and services using the links below.