AES complete Custom Conformal Coating Extraction Installation

This case study will follow the process of the project detailing the existing measures within the facility and further we will explain the AES approach to the project and the final solution proposed and implemented for the client.

Existing Controls

Within this facility a Conformal Coating process is needed to protect the PCB boards within the products. Conformal Coating consists of a chemical spray which is applied directly onto the circuit board in order to give protection and ‘conforms’ to the circuit board’s properties. This coating provides the PCB with further protection in harsh environments e.g. moisture/fumes/gas/dust and gives surface insulation resistance, increasing the board’s durability. This process also compliments the operational integrity of the circuit board and improves corrosion resistance from contaminants within the boards working environment.

Conformal coating within this facility was carried out using an aerosol chemical based spray, containing harmful VOC’s (Volatile Organic Compounds) and solvents which require extraction under the COSHH 2002 Regulations and HSG258. The facility was equipped with a small filtered unit that was not up to the task during the conformal coating process, and the ongoing cost of the replacement filters for the system were also not cost effective for the client. There was also no provision for extraction during the drying process after the conformal coating had been completed, during this drying period the coating still gives off harmful fumes that could potentially damage the health of the operators.

Solution

The first step for this project was to carry out a consultative visit in order to survey the current system. It was noted at this stage that the extraction for the conformal coating process needed to be improved and an extraction facility for the drying process was also essential. The existing controls in place were not adequate enough to provide effective extraction of the contaminant, and a provision for the drying process was needed therefore a full re-design and replacement of the system was required.

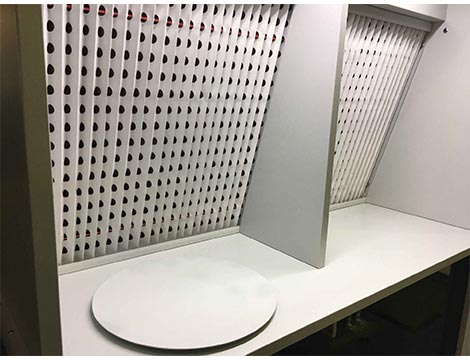

AES installed and commissioned a custom conformal coating spray booth, complete with a turntable and a partition to provide space for drying of circuit boards within an extracted environment to fully protect the operators from the harmful substances during the conformal coating process. This two-in-one solution allowed the operators to fully coat each circuit board without having to handle the board until completely coated, and also provided a safe drying area.

AES continue to provide innovative extraction solutions for all industries, applications and processes with a number of new and exciting projects coming this year.

Get in touch with us

Contact us using the links below to speak to one of our consultants. You can ask us a question, look up useful resources or call us on 0800 032 0895 for an instant response.