AES specialise in the design of bespoke extraction solutions to fit specific customer requirements.

Following your initial enquiry we will carry out a site visit and provide you with advice including a range of options to meet your requirements and budget. The design process will include a number of key stages detailed below.

Our design process keeps our customers connected

From initial consultation to final project delivery, the AES design methodology keeps customers involved during each stage of their LEV installation.

Initial Consultation/Site Visit

System Design

Project/System Proposal

CAD Design/Drawings

Identification of Contaminant Type and Hazards

The key purpose of any LEV system is to ensure that the contaminant is controlled to a safe level. As different substances can present different hazards and levels of harm, a system which is suitable for a low toxicity substance may not be suitable for a more harmful substance. It is essential therefore that all harmful substances within the process are identified so that the hazards presented by them can be assessed. This information may be provided by the client or their suppliers in the form of Manufacturers Safety Data Sheets (MSDSs) or other available published data.

When the substances have been identified the Workplace Exposure Limits (WELs) can be determined.

Where a mixture of substances are present the system will be designed to ensure that the most hazardous substance is controlled to acceptable levels. If the WEL for a substance is not available, COSHH Benchmarking can be used to determine the acceptable safe level for effective control.

In addition to the occupational health hazards presented by the substances, other factors must also be considered; including the flammability/explosive properties of the substances and compatibility with the materials used within the LEV system. This will determine if e.g. ATEX components are required or if specialist materials need to be specified for corrosion resistance.

Process Analysis and Hierarchy of Control

The Control of Substances Hazardous to Health (COSHH) Regulations 2002 sets out the hierarchy of control for hazardous substances. This means that employers must consider all routes of exposure and ensure that processes and working practices are designed to minimise harmful emissions. Examples of this may include enclosing processes or grouping processes that emit dust or fume together so that they can be more easily controlled.

As part of our design process we will advise clients where reductions in emissions can be achieved by following the hierarchy of control. By following this process the LEV system can be designed to provide the most efficient and economically effective solution.

System Design

All of our design engineers are qualified to the BOHS accredited P602 standard in Local Exhaust Ventilation design.

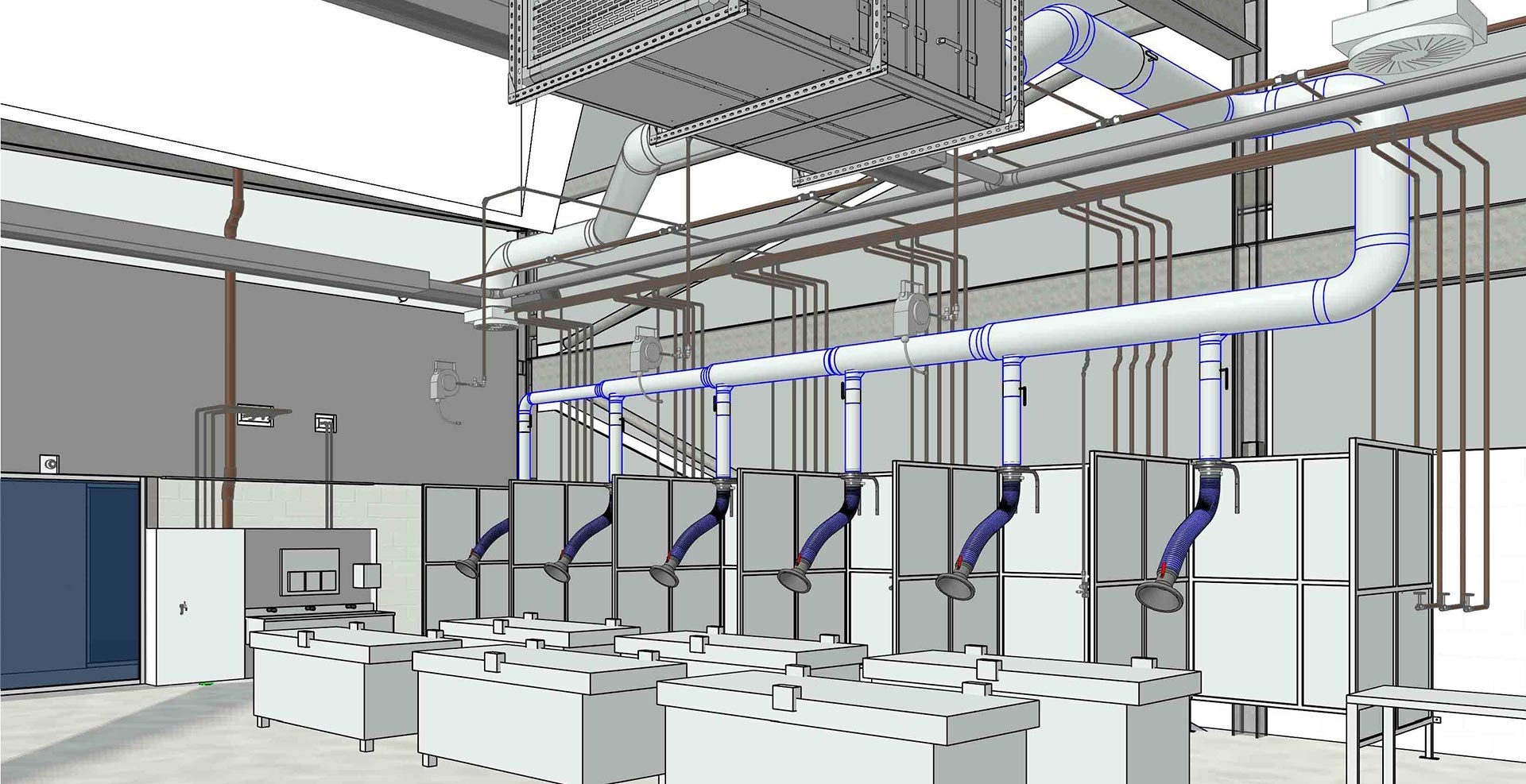

The first step in designing the system will be the selection of the correct capture hood type. This may include connection to extraction spigots on existing machines, capture hoods on extraction arms or bespoke hoods tailored to fit your process. The total system flow rate requirements can then be calculated based on hood flow rate requirements and the maximum number of extraction points used at any one time.

The final stage will be the selection of appropriate filtration and the requirements for discharge.

In addition to the basic design criteria covered in the previous stages, it is important to consider how the operator will interact with the system’s components. This may include arrangements for dust collection and disposal, system controls including the consideration for automatic or manual valves and interlocking with process equipment. For every LEV system the Health and Safety Executive (HSE) recommends that airflow indicators are fitted to extraction hoods which AES include as standard for every project.

Project/System Proposal

Following our site survey and system design, we will prepare a detailed proposal which includes the following:

- System overview

- Scope of works

- Detailed system specification including duct velocities. flow rates, equipment type

- Responsibilities (i.e. clarification of what AES will provide and client requirements e.g. power supplies)

AES are key distributors for a wide range fo leading UK and European manufacturers in extraction technology and can offer a range of products to meet your budget. AES are proud to offer one of the most comprehensive ranges of lev equipment within the industry ranging from large industrial extraction units to spare parts and replacement filters for all systems.

You can view our list of suppliers here.

CAD Design/Drawings

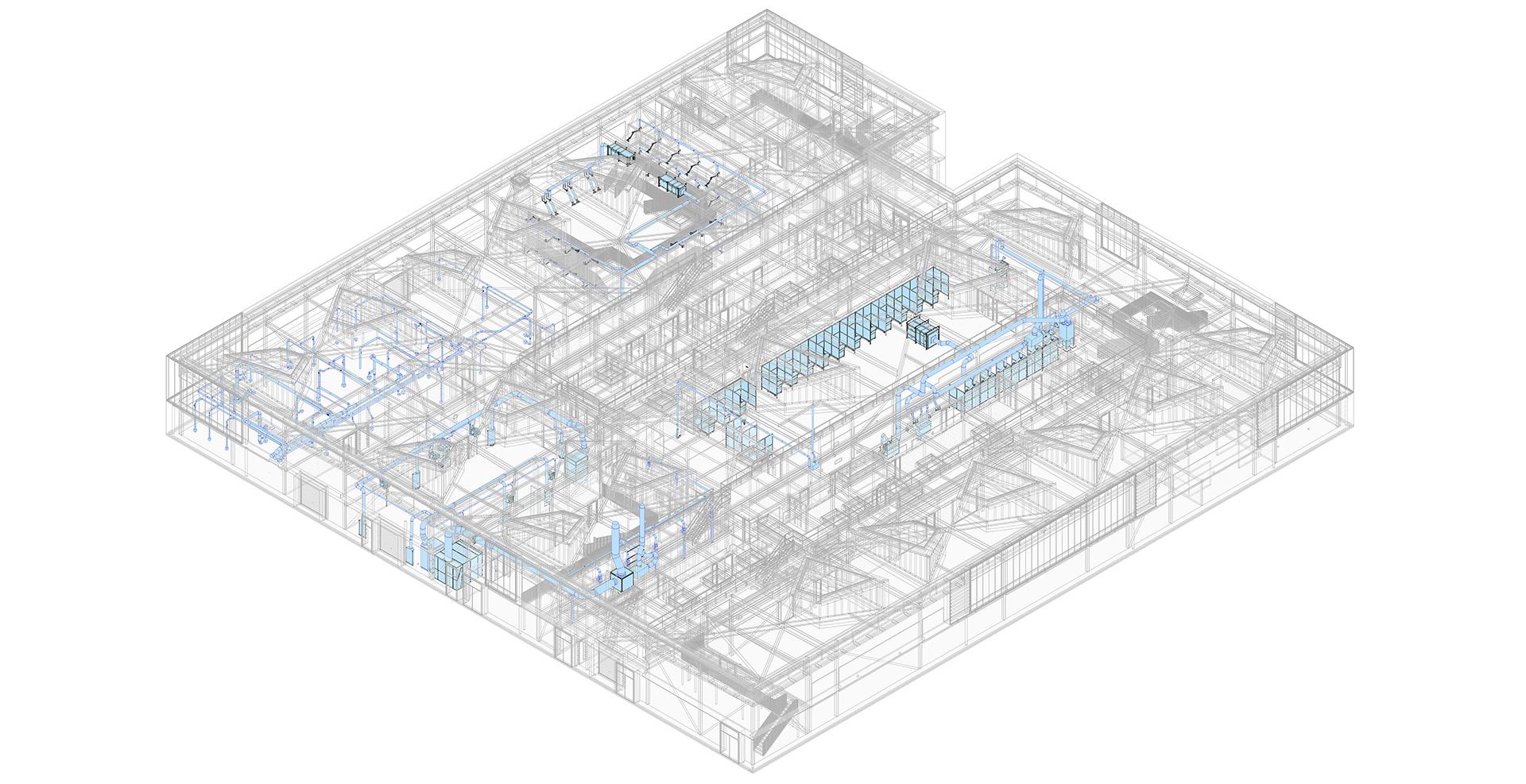

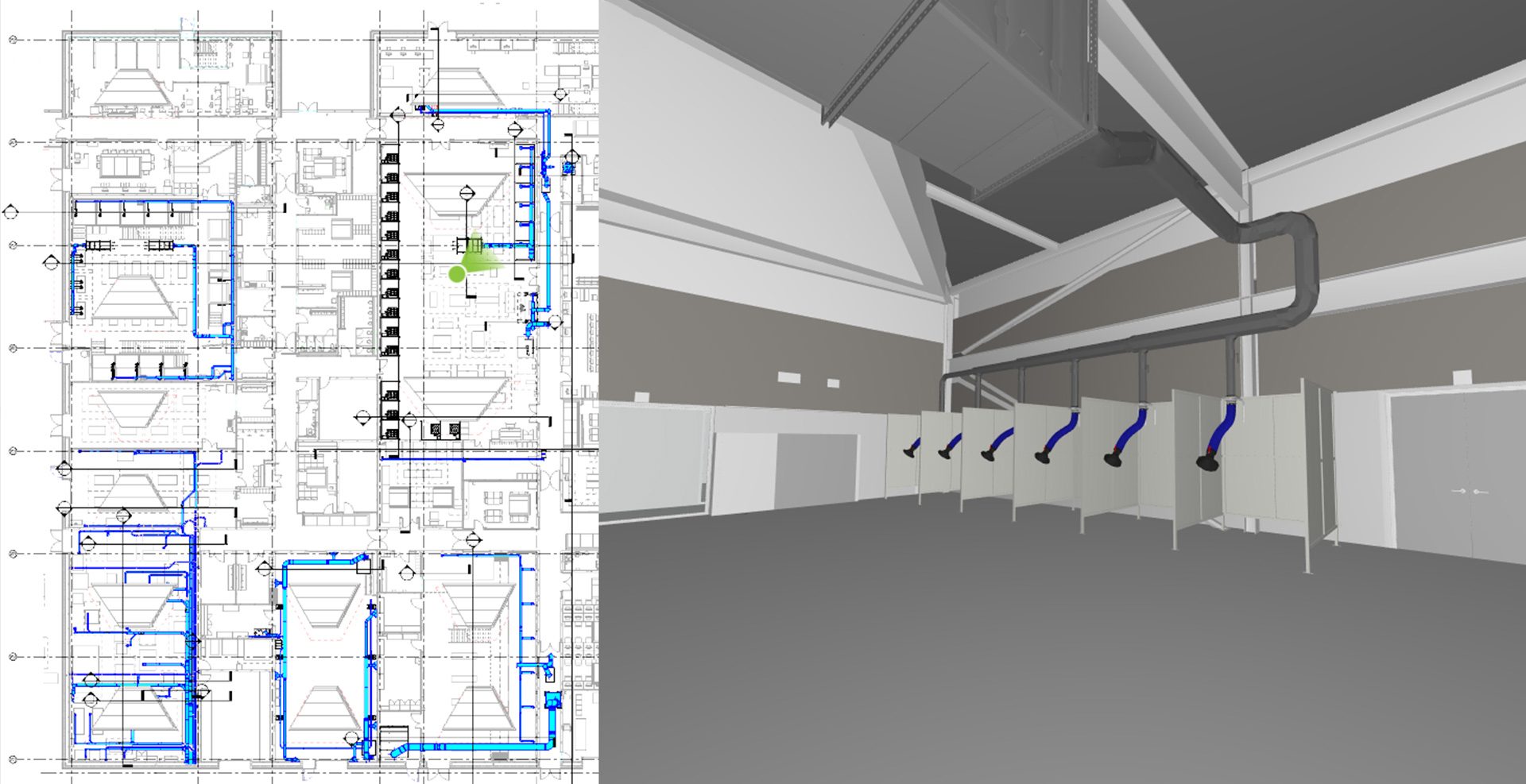

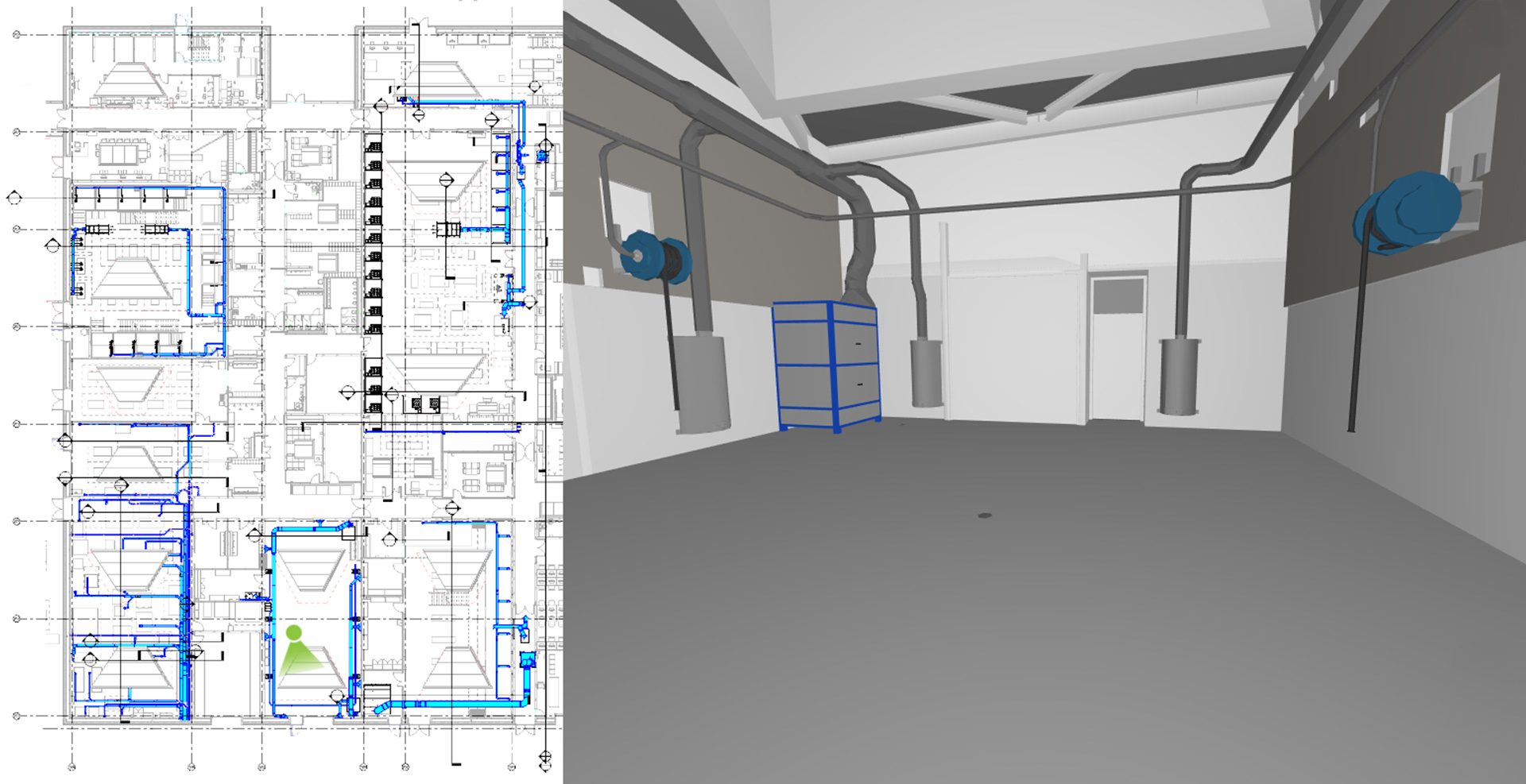

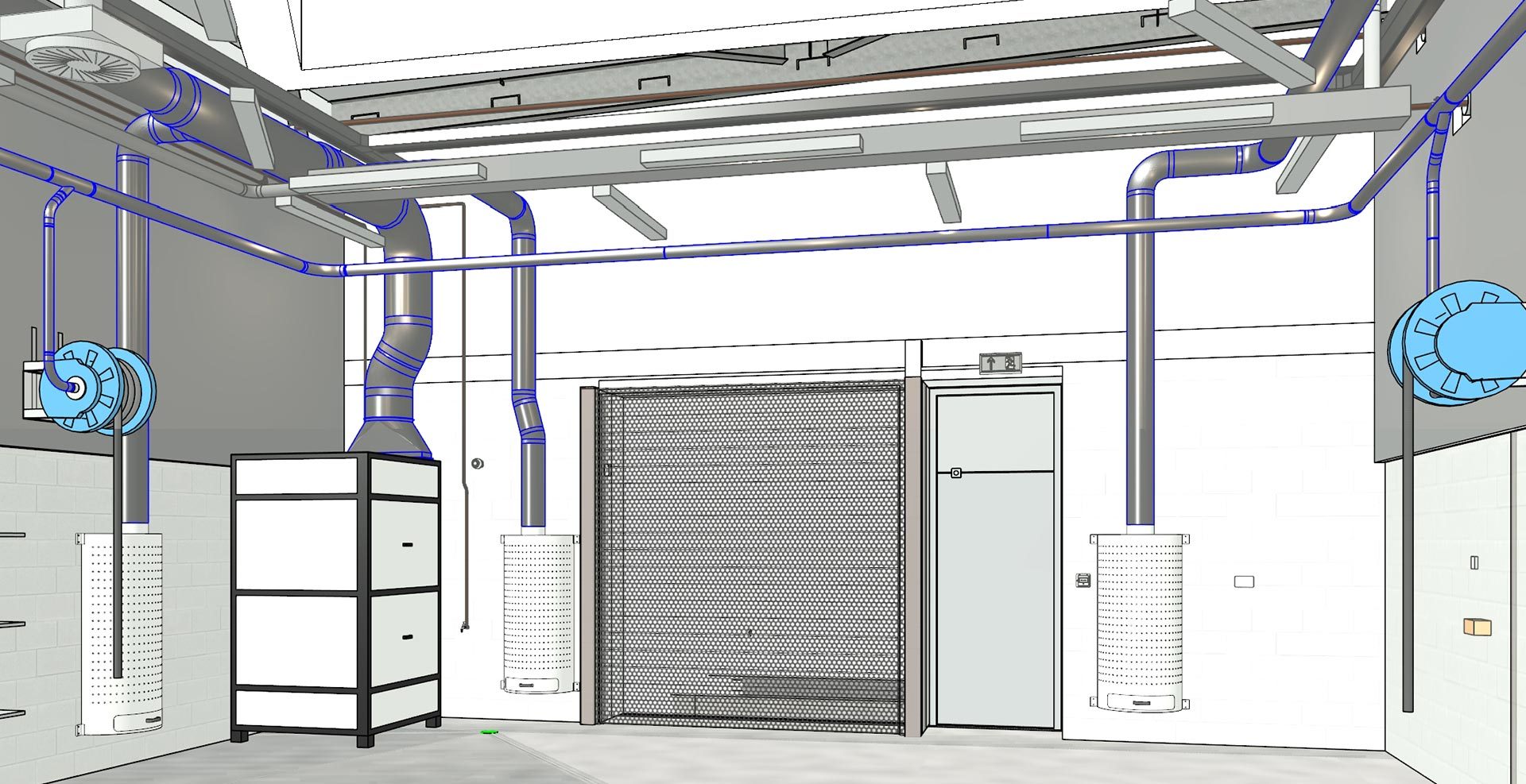

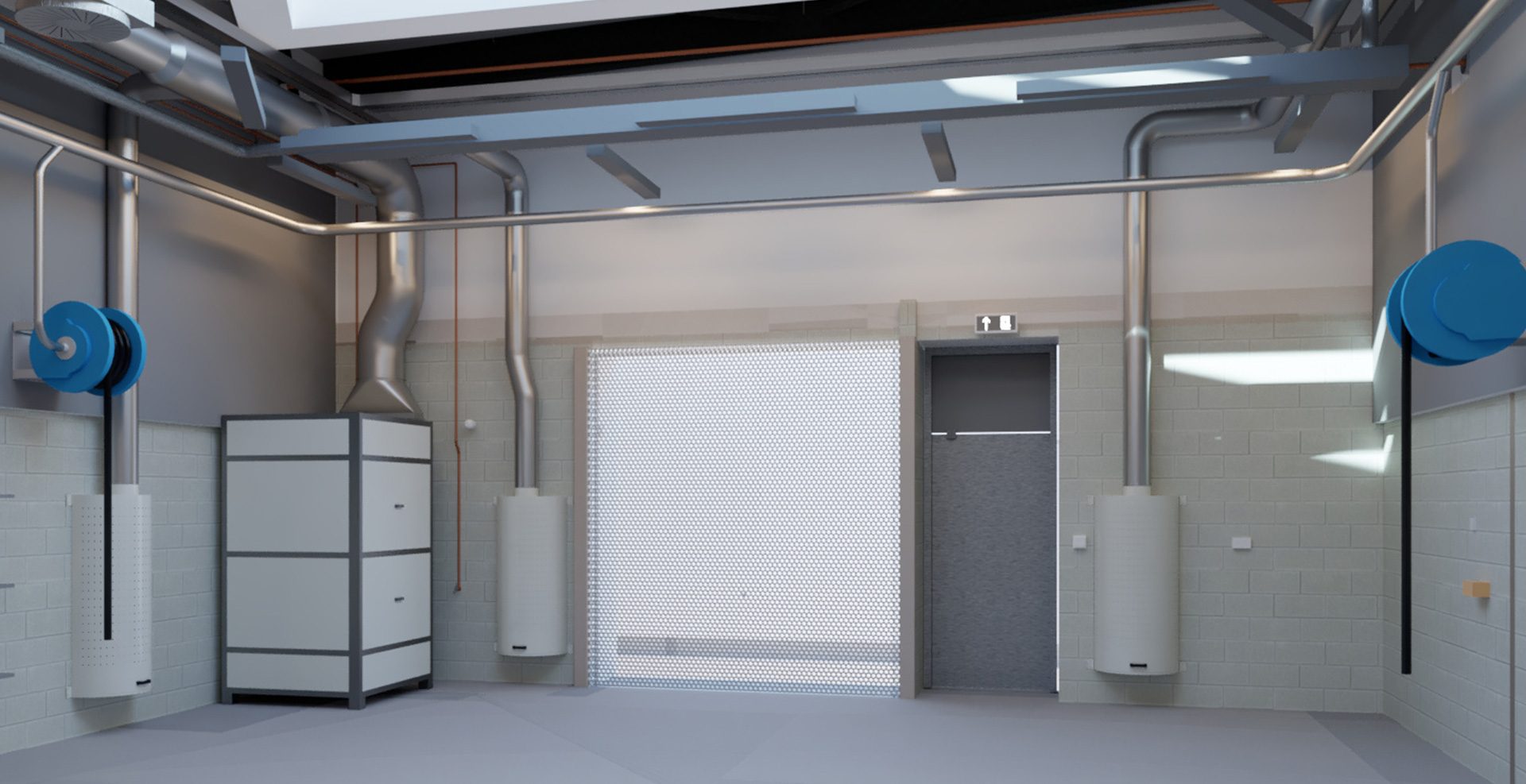

On receipt of an order the AES design team will create a 3D CAD model from the system specification using the Autodesk REVIT 3D layout platform.

This will show the capture hoods, duct layouts, filter location and discharge arrangements. Drawings will be submitted to the client for discussion and final approval before installation commences.

The addition of 3D models for our installations helps both our installation team and our clients visualise the final solution before the works have commenced, and further gives our customers confidence of how the facility will look on completion of the project.

Get in touch with us

Contact us using the links below to speak to one of our consultants. You can ask us a question, look up useful resources or call us on 0800 032 0895 for an instant response.