The Airline range of filter systems from NOVUS

A centralised recirculating solution for the extraction and filtration from processes such as robotic welding cells, plasma cutting machinery and CNC fabrication equipment.

Unique and Original Design

Traditionally, filter cartridges are fitted vertically or horizontally within conventional systems. This is the standard approach, but it may not propose the best solution.

With the Airline, filter cartridges are fitted in a vertical standing position and at a unique angle. Thanks to this position, the flow direction and gravity as well as the direction of particle movement are aligned to improve filtration efficiency.

The Airline can therefore guarantee effective filtration and cleaning using these internal design innovations.

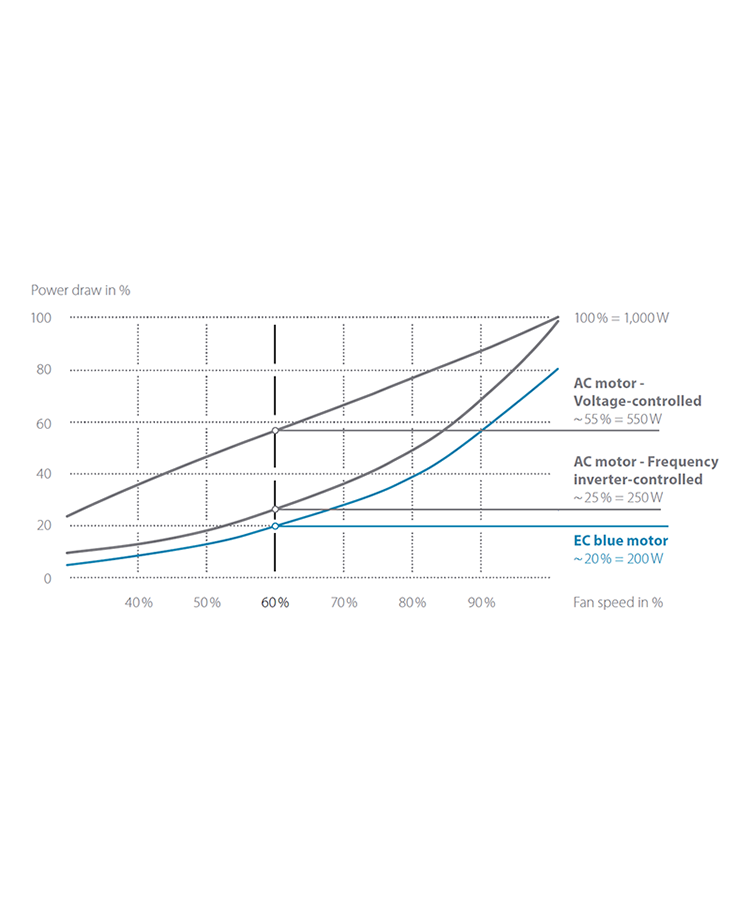

The filter cartridges age slower due to the effective cleaning with the compressed air being aligned with each element, in turn this extends the overall service life of the filters and low flow resistances coupled with minimal internal pressure losses also reduce the power consumption.

The Novus Airline can be supplemented with modules in accordance with your needs and extended with additional performance parameters if required. There is also the option to include multiple Airline systems in series to achieve higher airflow rates and increased power for larger processes.

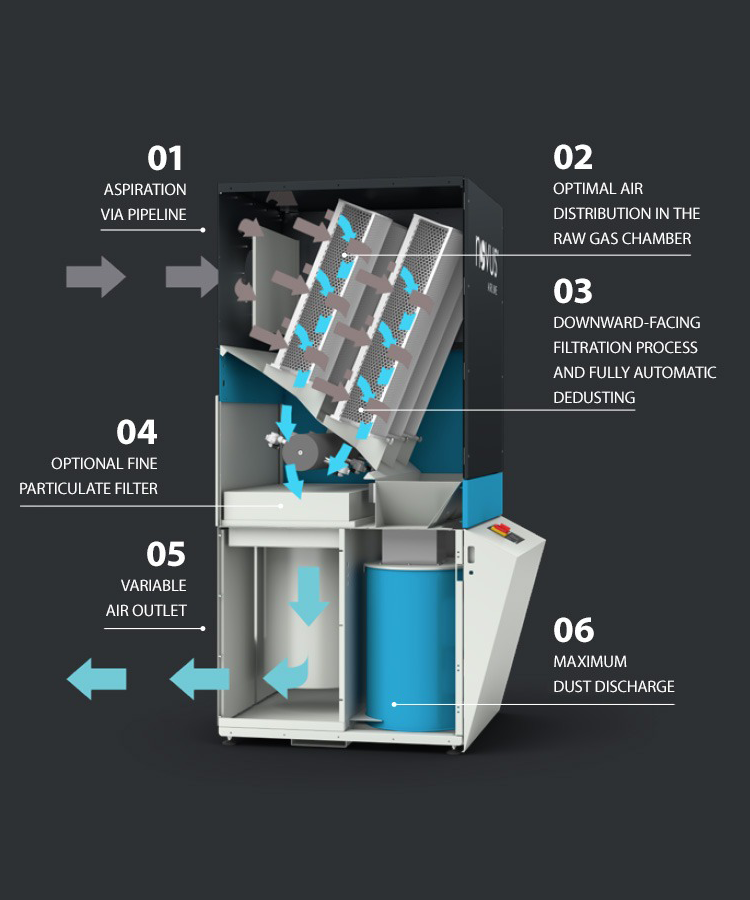

How It Works

Extracting directly from a process such as a welding robot cell or a plasma cutting table, contaminated air passes through the pipeline into the Airline extractor and is routed towards the filters.

The airflow is distributed optimally in the filter chamber, forcing the air to change direction with an immediate deflector plate at the inlet. Within the chamber there are modules of four or six filter cartridges which are automatically cleaned via. compressed air.

Within the filter chamber, the 3-1 principle takes effect and the filter cartridges clean the air with an efficiency of 99.995%. The purified air is then fed back into the room. A filter class H14 can also be installed upstream of the fan unit, as an option.

Built for a production environment the airline units are able to run continuously in line with the process concerned.

Various Capture Options

As with all projects, it is the framework of conditions and individual process and user requirements which determine the type of suitable extraction system.

If local factors or the process require collection close to the source of emissions, a stationary extraction unit such as the Airline is ideal. This type of system also makes sense if appropriate machine connections are available to directly capture from the process or piece of equipment.

The airline can also be used where direct machine connection is not available, with the addition of ducting runs and the use of capture hoods, it allows the extractor to be used easily at workstations, machines, or even in difficult to access environments like robot cells, or wherever hazardous emissions is released.

Airline units can be utilised with extraction arms, nozzles and downdraft benches to suit any fabrication workshop or production area.

Effective Extraction of Dust & Fumes

The design of each Airline system depends on specific properties for each process. AES can design the system configuration to suit exactly what is required for your working environment.

For example, higher volumes of air can be achieved with relatively small dimensions for dry, granulated dusts. A different approach is needed for slightly adhesive emissions or smaller processes emitting fumes.

Various design options – per module, the Airline is available in variants with four or six filter cartridges.

While one Airline with four cartridges achieves a nominal capacity of 4,000 m3/h, designs with six filter cartridges can reach an airflow capacity of 10,000 m³/h.

Airline units can also be installed in series to provide a modular line of extractors each serving the same process. As a result, volume flows of up to 60,000 m3/h or more can be implemented in this way. Every Airline can be equipped with an autonomous control unit for the fan, pressure sensor equipment and variable speed is standard on all configurations.

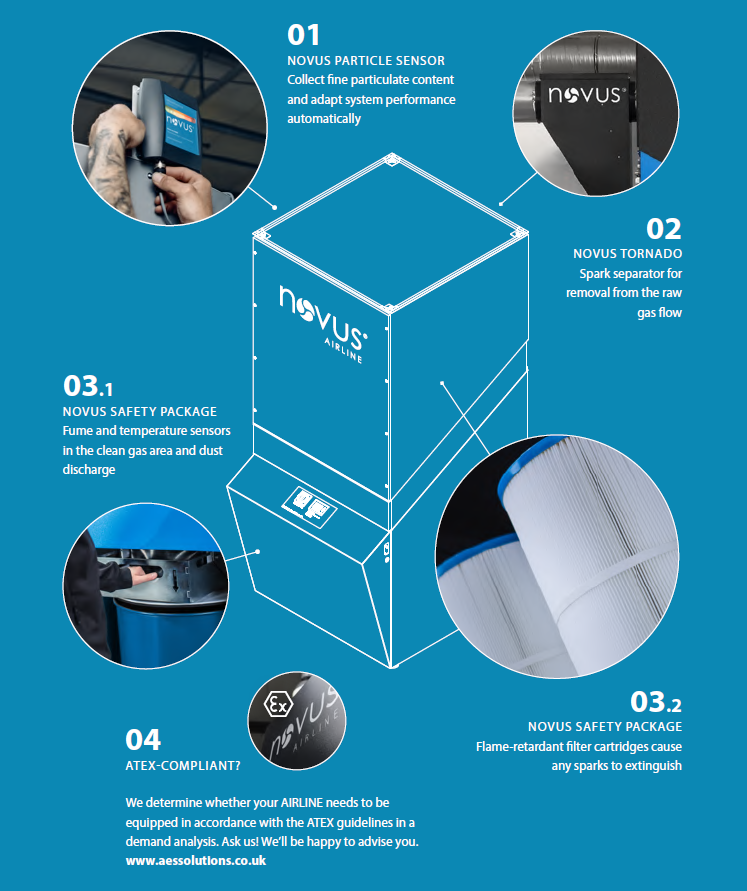

Novus Airline Features

Contact AES today to speak to our technical team of staff who will find the correct extraction products to suit your requirements.

Email Us

Get in touch with us

Contact us using the links below to speak to one of our consultants. You can ask us a question, look up useful resources or call us on 0800 032 0895 for an instant response.

Get in touch with us to find out how AES can help you create a safer workplace.

Get a quote