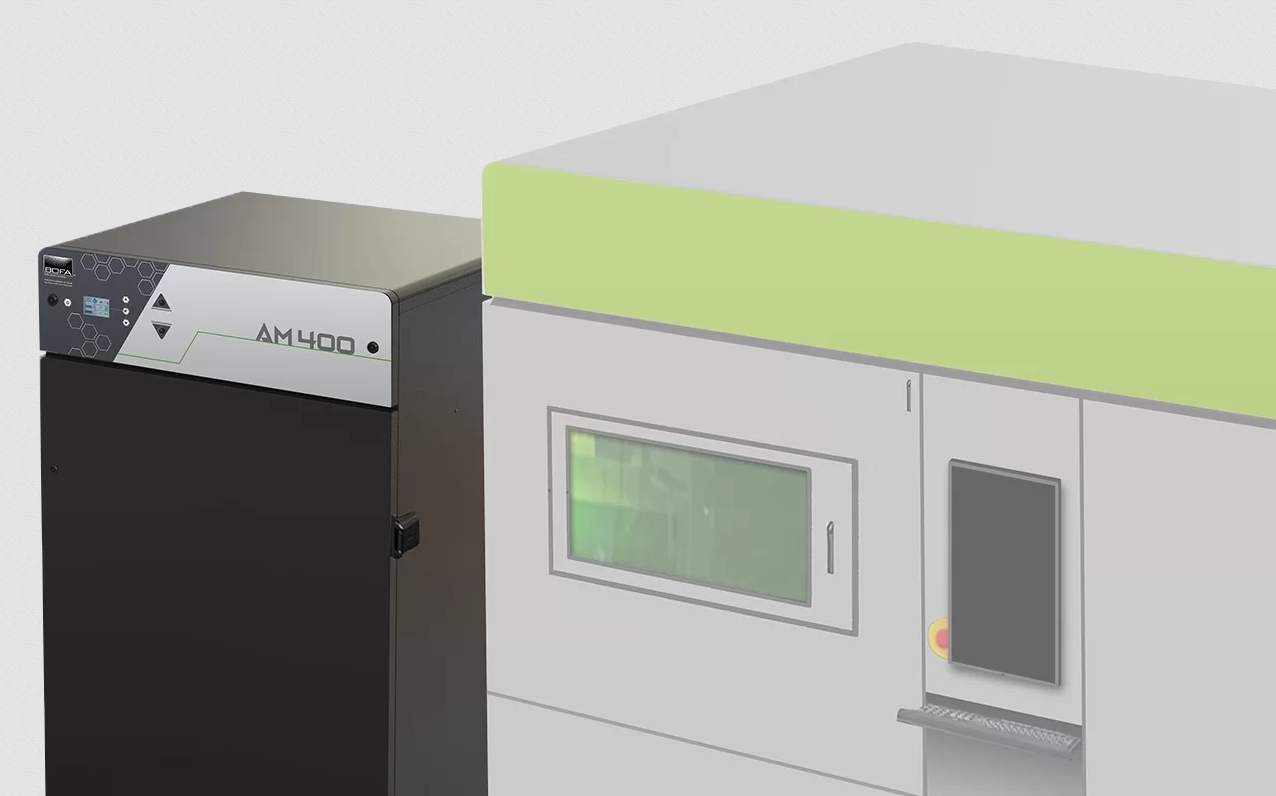

BOFA International

BOFA, one of our manufacturing partners in the LEV industry are once again developing an innovative and industry leading product for additive manufacturing.

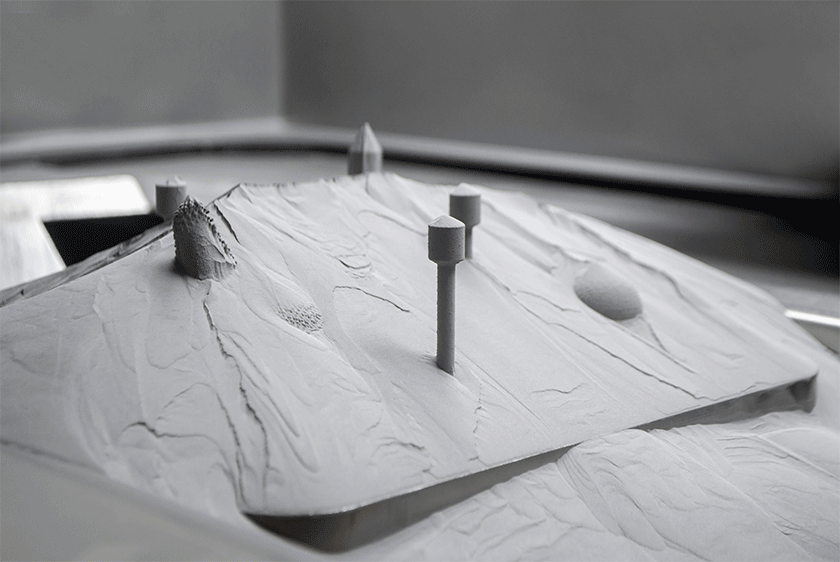

A World-first in Additive Manufacturing

The AM 400 extraction system is, according to Bofa, a world-first in additive manufacturing fume extraction making the exchange of filters in powder bed fusion processes safer, faster, and better for productivity.

The system offers high airflow potential, up to a maximum of 190 cu ft/min and a maximum operating pressure of 250mBar, with low leakage at <30 ml/min @ -10mBar.

The iQ system

The iQ status indicator offers on-screen system alarms and easy identification of system performance. With this intelligent system, users can also download log files to examine issues after the event.

The AM 400 is also equipped with a remote start / stop feature, which ensures the extractor turns on or off with the host unit – users don’t have to think about separate operation of the power as this is handled automatically.

Filtration & Applications

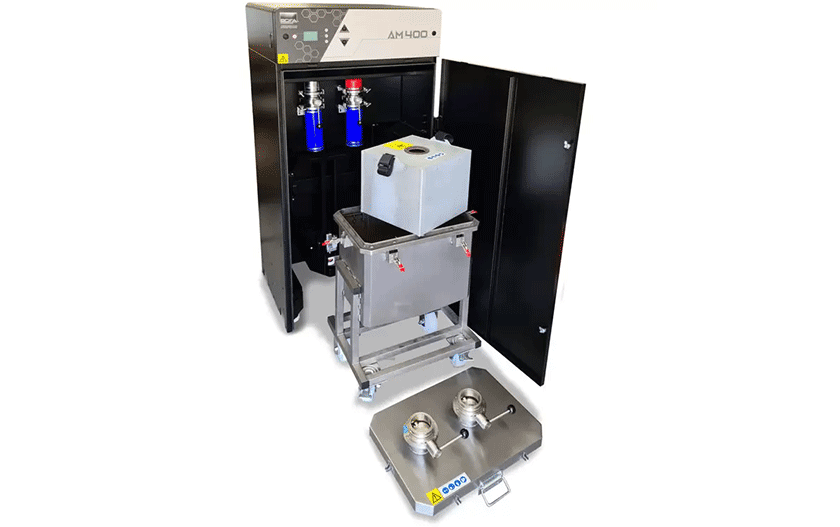

The AM 400’s filters are contained inside a separate housing and sealed. Each filter change can be completed safely and quickly, in a location remote from the process floor.

This new and innovative extraction solution was developed in partnership with a leading additive manufacturing company and specifically designed for powder bed fusion applications, such as:

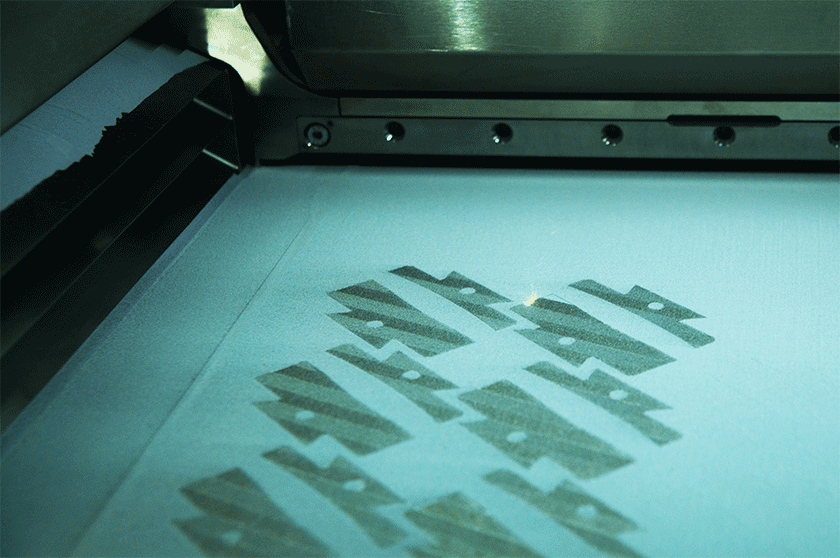

- Direct metal laser sintering for metals

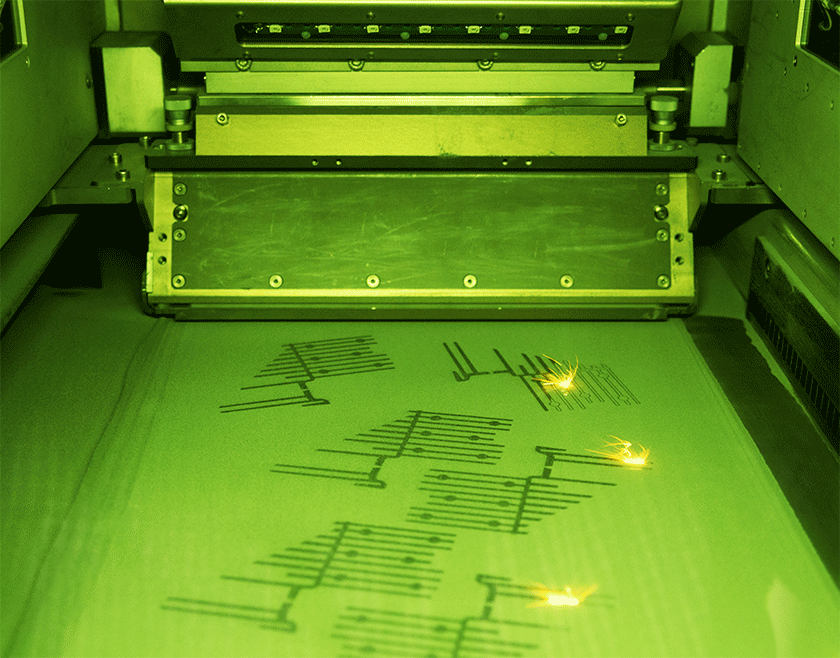

- Selective laser melting for polymers

It is also ideal for use in metal 3D printing applications using a controlled, oxygen-free

environment for a range of markets:

- Pharmaceutical

- Nuclear

- Aerospace

- Aeronautical

- Medical

- High-value metal printing

Direct Metal Laser Sintering (DMLS)

Selective Laser Melting (SLM) polymer applications

Available to order on our e-shop

VIEW PRODUCT