The Design of LEV systems for Education is at the core of our business

For 18 years, AES have been an industry leading design, installation and service support business for Local exhaust Ventilation for education. Our team of 40 staff are committed to providing the highest quality solutions for the staff and students of the UK.

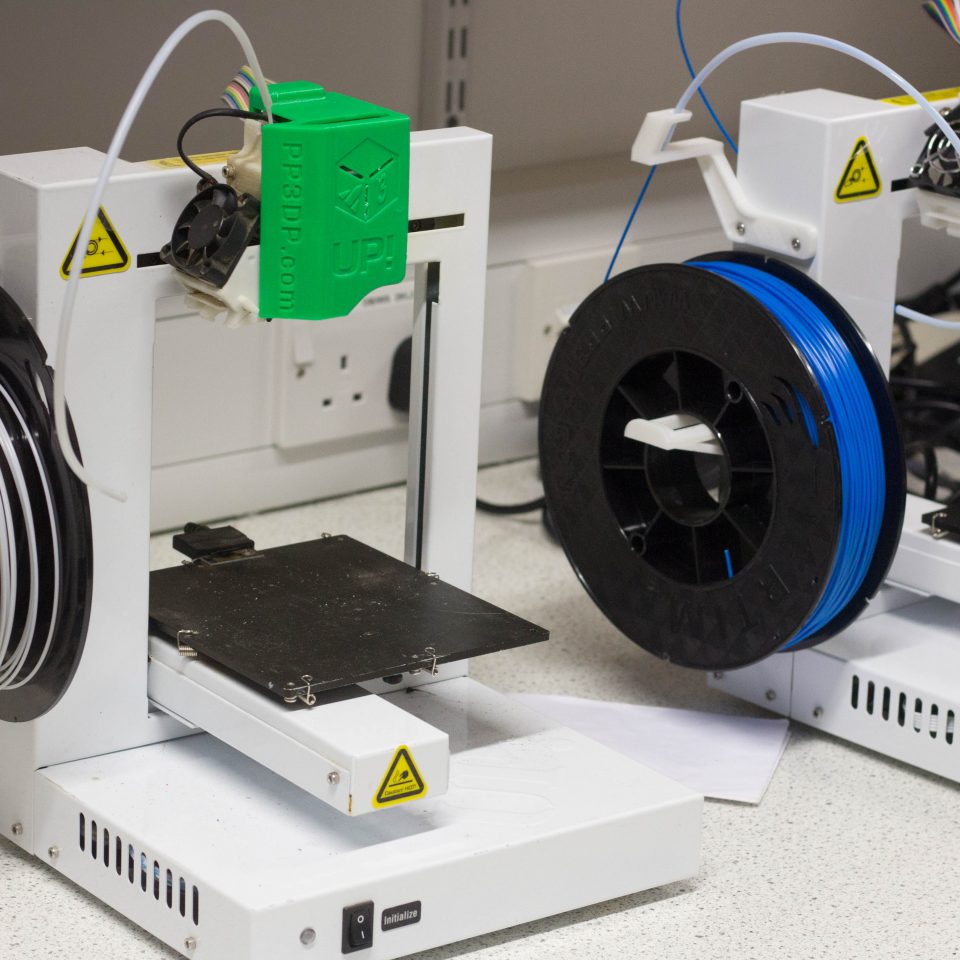

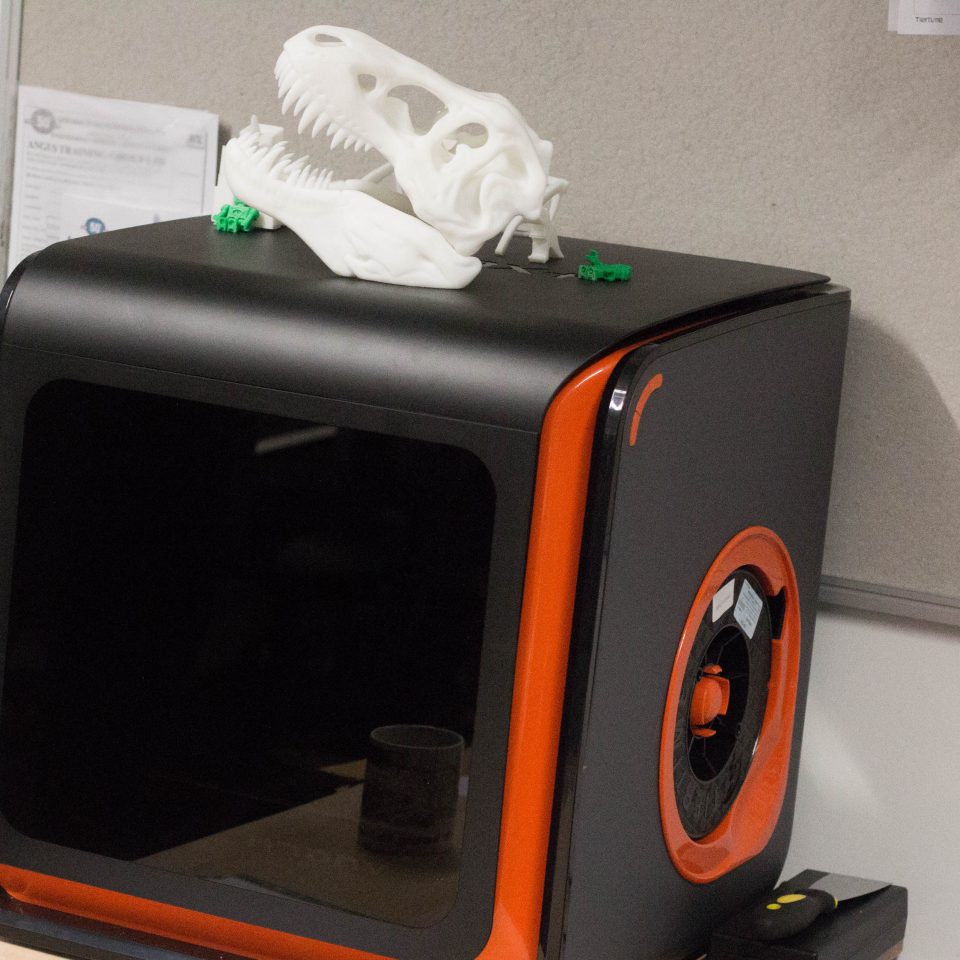

Our LEV systems are tailored and designed for the specific contaminant type and workplace. We have designed and installed LEV systems of varying types for processes such as woodwork, metalwork, solder, 3D printers, laser cutters, routers , solvent fume and kilns.

Our team can work with staff in order to find the best solutions for the practices occurring. This includes choosing the correct method of extraction that will adequately remove fumes, dusts or vapours – whilst providing the least intrusive change to the way in which workers carry out tasks.

If you are unsure of what kind of system your workplace requires, our team of experts can explain the range of solutions available and help you to choose a suitable system for your work processes.

You can call us on 0800 032 0895 or send an email to our team at info@aessolutions.co.uk and we will be happy to help.

Our Extraction Solutions for Education

Wood Dust Extraction

Wood dust extraction solutions for education. Under the COSHH regulations and HSG 258 it is a legal requirement for employers to extract and filter harmful wood dust from machinery and processes.

1 of 3

2 of 3

3 of 3

Extraction for dust & fumes in technology classrooms

Processes such as laser cutting and 3D printing can cause potentially harmful fumes to enter teaching and working areas. Our range of solutions include compact extractors to suit all rapid prototyping processes, recirculating clean air back into the the rooms without the need for installation or ducting.

1 of 4

2 of 4

3 of 4

4 of 4

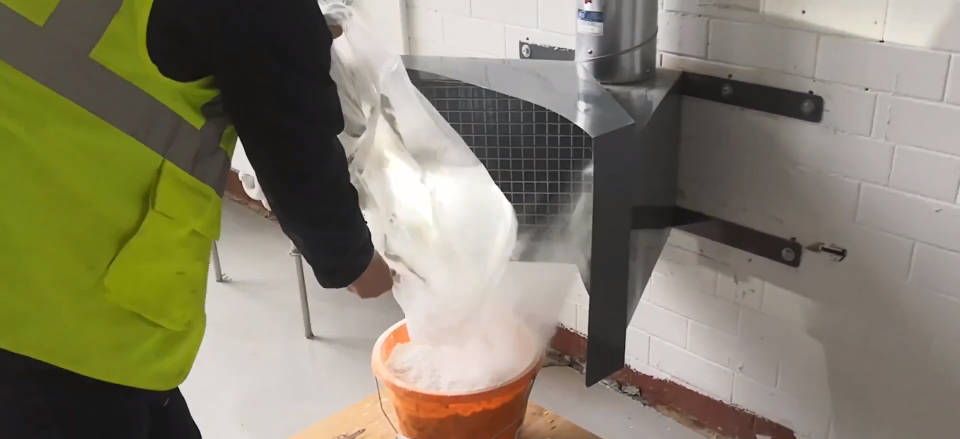

Extraction from Brazing Hearths, Forges and Welding

Within most secondary educational workshops there is a dedicated area for hot works and heat treatment equipment. Within these areas dangerous fumes and heat are given off by the various processes taking place, Our extraction solutions like in the example to the right show a typical set up for a hot works area, providing safe and effective extraction for the workshop.

1 of 1

Extraction for exhaust fumes in education

Fumes created from diesel engines and petrol powered machinery need to be extracted from the internal work space. AES have experience dealing within areas for all types of vehicles including standard maintenance workshops, HGV's, Locomotives and Aerospace.

1 of 2

2 of 2

Extraction for dust within trade training areas

Various trades require dealing with materials which cause dust to become present in the working area, within weighing areas for plasterers this can cause the operator to be in contact with dust particles harmful to health. AES have installed multiple solutions to suit these issues like the fixed capture hood example on the right.

1 of 2

2 of 2

Solder fume extraction for Universities and Colleges.

AES supply systems designed for electronics soldering applications that generate fume comprising; resin acid particulate and gaseous organic compounds. Typical in most electronics teaching classrooms or design workshops, soldering is a common process involving students working on projects or learning new skills. There are various options available from small and compact under-bench units like on our right, to fully installed central systems for larger areas.

1 of 2

2 of 2

Extraction for welding fumes.

Empowering the workforce of the future by harnessing essential manufacturing skills such as welding, we design and install weld training areas that familiarise the students with essential health and safety measures they will work alongside throughout their careers in industry. From single welding bays to full factory style fab shop layouts, AES can help you design and complete your welding areas to the highest standard.

1 of 2

2 of 2

Compact Wood Dust Filter Systems

AES offer a range of compact wood dust extractors for indoor installation that can be directly connected to single machines, CNC centres or service small to medium sized workshops. The Deduster Range allows for powerful and efficient extraction at source. Find out more by clicking the link below.

Click below to find out how AES can help with your enquiry today.

Get a Quote