Solder Fume Extraction for Electronics

Rosin-based solder flux fume is now regarded as one of the leading causes of occupational asthma in Britain. Rosin is used mainly as a flux in the electrical and electronics industries where it is heated with the solder (usually tin/lead) to make electrical connections. It may also be used for soldering in plumbing and other pipe-fitting work. When inhaled, rosin-based solder flux fume can lead to occupational asthma or make existing asthmatic conditions worse. The fume can also cause irritation to the eyes and upper respiratory tract.

There are various methods of controlling solder fume in the workplace or teaching environment. AES can provide a wide range of solutions for the extraction of solder fumes to meet your requirements and budget.

Benchtop Extraction Units

For single workstations or multiple manual soldering applications, these small form factor units can fit neatly under most workbenches. These popular units can come equipped with extraction arms fitted with multiple nozzle configurations, mounted to the table top itself or directly from the extraction unit. Stainless steel extraction arms can also be supplied for high temperature soldering and brazing applications.

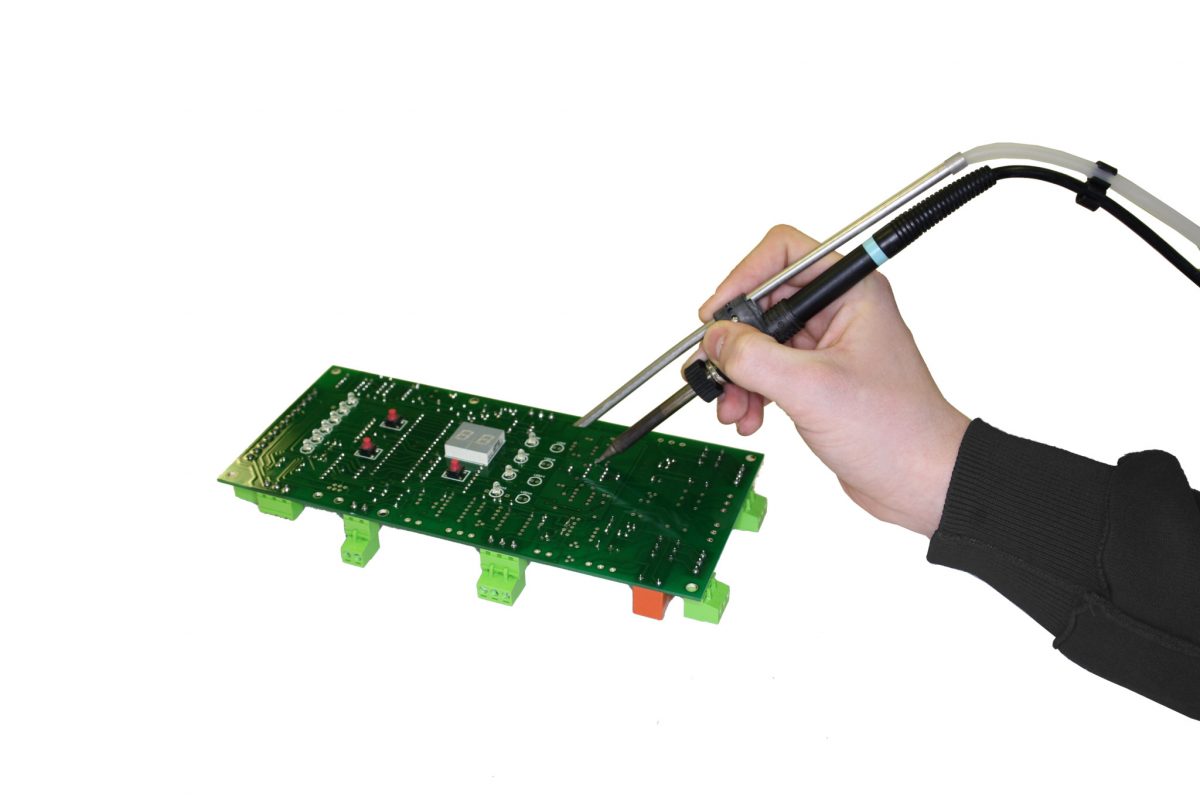

Tip Extraction Systems

For hand soldering, tip extraction systems can be used to remove the solder fume/smoke directly from the tip of the soldering iron. These units can be supplied for single workstations up to 100 tip extraction points for large production lines.

Central systems

Central extraction systems can be installed for facilities with multiple soldering stations, or with multiple electronics manufacturing production machines. These systems offer a large volume/vacuum solution for larger facilities and can be designed to complement the flow of any electronics production line.

See our full range of solder fume equipment on our website today

SHOP NOW